Master Your Marketing with Automation

In today’s fast-paced digital world, businesses are constantly looking for ways to streamline their marketing efforts and maximize efficiency. One of the most effective tools for achieving this goal is marketing automation. By leveraging automation technology, businesses can save time, increase productivity, and ultimately drive better results.

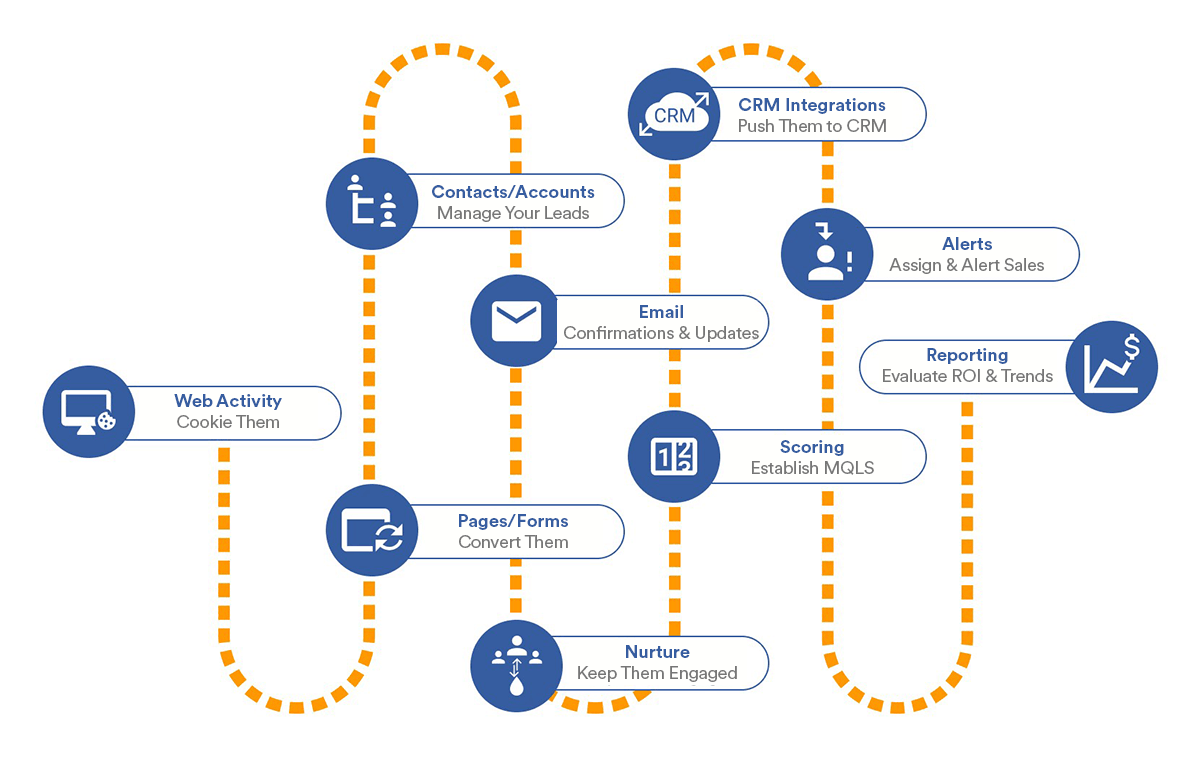

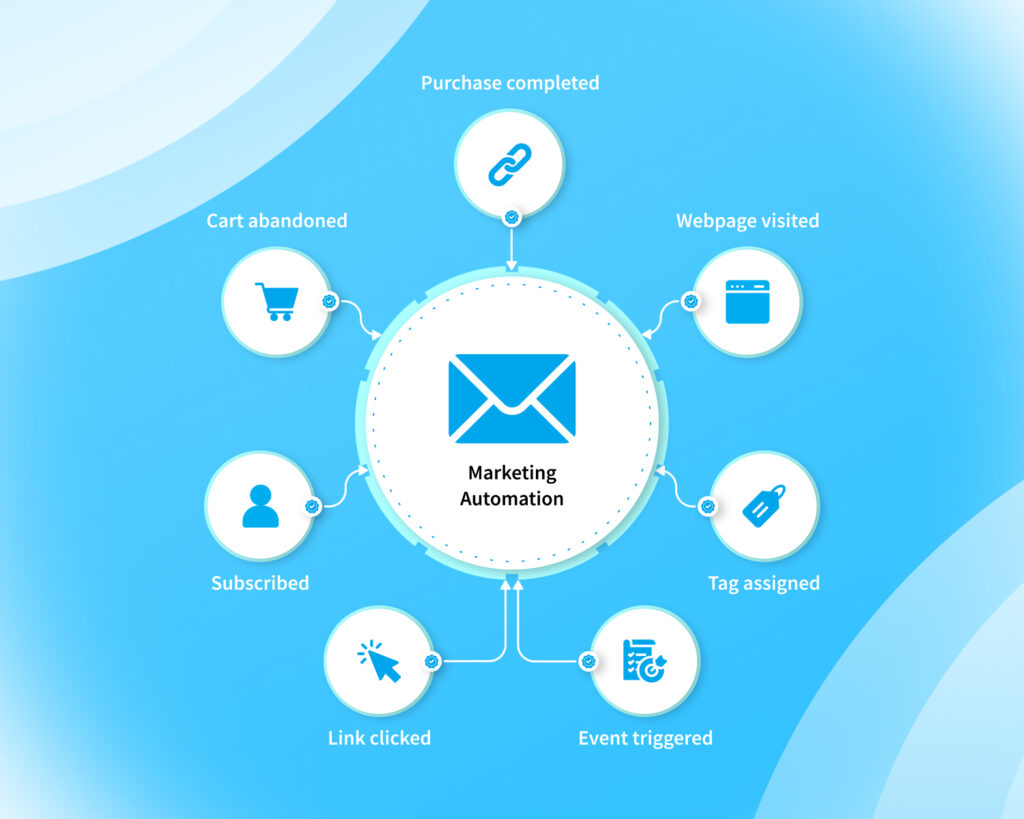

Marketing automation refers to the use of software platforms and technologies to automate repetitive marketing tasks and workflows. This can include everything from email marketing and social media management to lead generation and customer relationship management. By automating these processes, businesses can free up valuable time and resources, allowing them to focus on more strategic and creative aspects of their marketing campaigns.

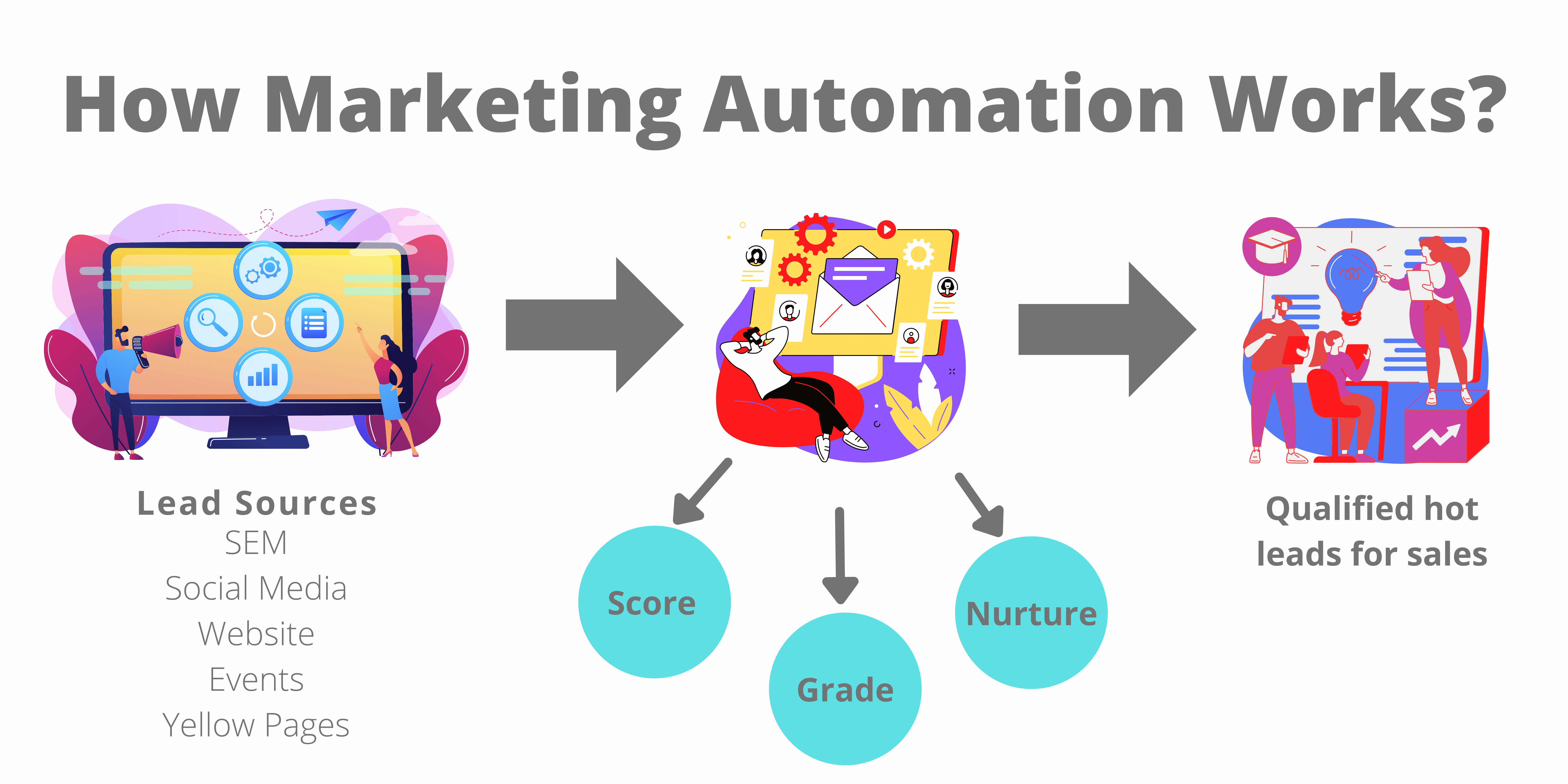

One of the key benefits of marketing automation is the ability to personalize and target marketing messages to specific audiences. By collecting data on customer behavior and preferences, businesses can create highly targeted and relevant campaigns that resonate with their audience. This not only improves the overall customer experience but also increases the likelihood of conversion and retention.

Another advantage of marketing automation is the ability to track and measure the performance of marketing campaigns in real-time. By analyzing key metrics such as open rates, click-through rates, and conversion rates, businesses can gain valuable insights into the effectiveness of their campaigns and make data-driven decisions to optimize future efforts.

Image Source: moengage.com

Furthermore, marketing automation can help businesses nurture leads and build relationships with customers over time. By setting up automated workflows that deliver personalized content and offers based on customer actions, businesses can create a seamless and engaging experience for their audience. This can lead to increased customer loyalty and lifetime value, as well as a higher return on investment for marketing efforts.

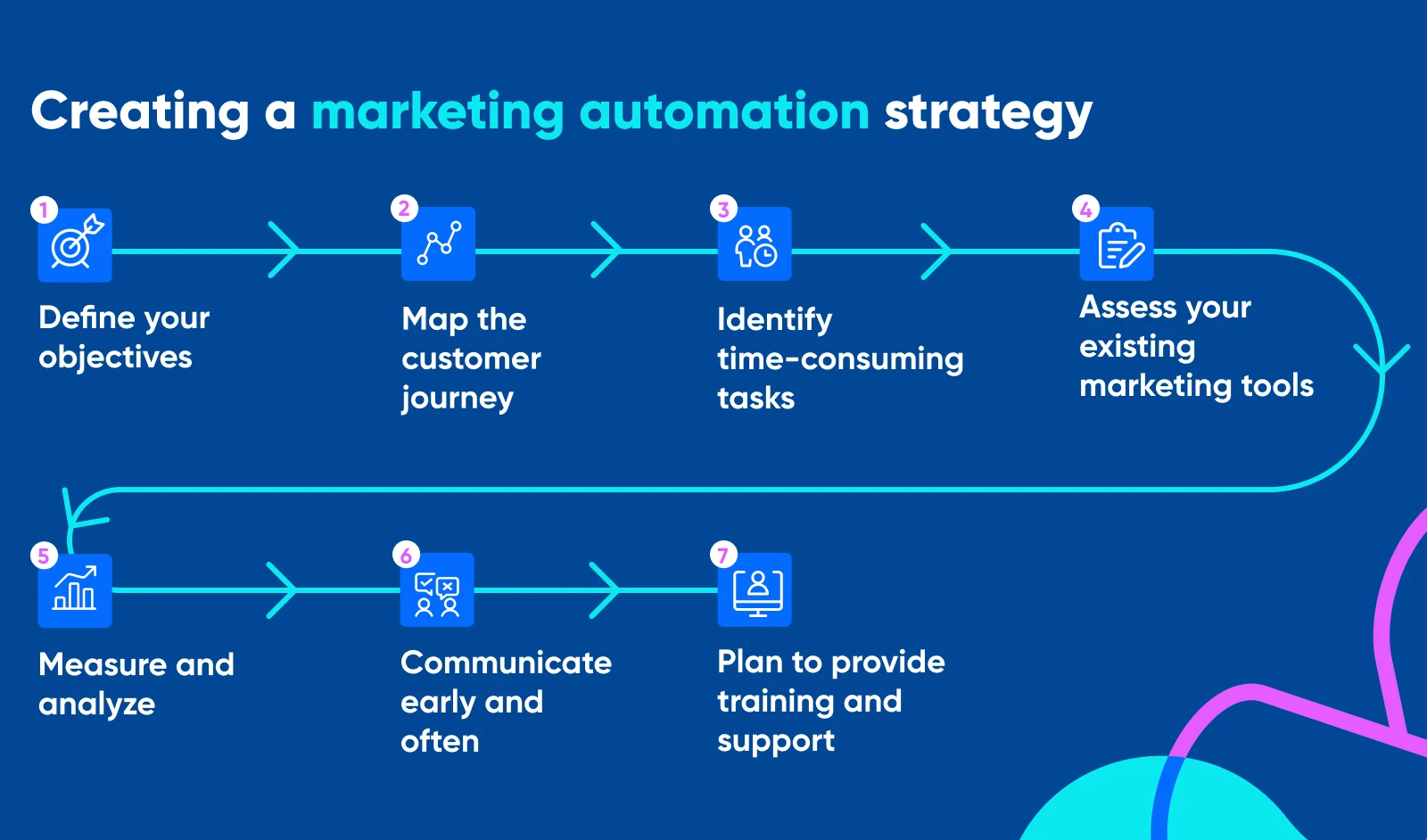

Implementing marketing automation may seem daunting at first, but with the right strategy and tools, businesses can quickly master this powerful technology. The first step is to clearly define your marketing objectives and identify the key tasks and processes that can be automated. This may include tasks such as email segmentation, lead scoring, and social media scheduling.

Next, businesses should choose a marketing automation platform that aligns with their specific needs and goals. There are many platforms available on the market, each offering different features and capabilities. It’s important to research and compare options to find the platform that best suits your business requirements.

Once a platform has been selected, businesses should work on creating targeted and engaging content that will resonate with their audience. This can include everything from email campaigns and social media posts to landing pages and lead magnets. By delivering valuable and relevant content to their audience, businesses can build trust and credibility, ultimately driving better results.

In conclusion, mastering marketing automation is essential for businesses looking to streamline their marketing efforts and drive better results. By leveraging automation technology, businesses can save time, increase productivity, and ultimately deliver more personalized and targeted campaigns to their audience. With the right strategy and tools in place, businesses can take their marketing efforts to the next level and achieve success in today’s competitive digital landscape.

Simplify Your Strategy and See Results

Image Source: rolustech.com

In today’s fast-paced digital world, it can be easy to get overwhelmed with the plethora of marketing strategies and tactics available. From social media to email marketing, content creation to SEO, the options seem endless. However, trying to juggle too many marketing tasks at once can lead to inefficiency and burnout.

That’s where simplifying your marketing strategy comes in. By streamlining your efforts and focusing on what truly drives results, you can see a significant impact on your business’s bottom line. Marketing automation tools can help you achieve this by consolidating your efforts and making your marketing campaigns more efficient and effective.

One of the key benefits of simplifying your marketing strategy is that it allows you to focus on what truly matters. Instead of spreading yourself thin across multiple channels and tactics, you can hone in on the strategies that have the most impact on your target audience. This could mean investing more time and resources into social media advertising, email marketing, or content creation – whatever drives the best results for your business.

By simplifying your strategy, you can also save time and resources. Instead of spending hours manually posting on social media, crafting email campaigns, or analyzing data, marketing automation tools can handle these tasks for you. This frees up your time to focus on more strategic initiatives, such as creating high-quality content or engaging with your audience in a more personal way.

Furthermore, simplifying your marketing strategy can help you stay organized and on track. With so many moving parts in a marketing campaign, it can be easy to lose sight of your goals and objectives. By streamlining your efforts, you can create a clear roadmap for your marketing initiatives and ensure that you are staying on course towards achieving your desired outcomes.

Image Source: sproutsocial.com

Another benefit of simplifying your marketing strategy is that it can lead to better results. By focusing your efforts on the strategies that have the most impact, you can improve your ROI and drive more conversions. Whether it’s increasing brand awareness, driving website traffic, or generating leads, a streamlined marketing strategy can help you achieve your goals more effectively.

In addition, simplifying your marketing strategy can lead to a more cohesive and consistent brand image. By focusing on the key messages and values that resonate with your target audience, you can create a more unified and compelling brand presence. This can help you stand out from the competition and build stronger relationships with your customers.

Overall, simplifying your marketing strategy is essential for driving results and achieving success in today’s competitive digital landscape. By leveraging marketing automation tools and focusing on what truly matters, you can streamline your efforts, save time and resources, and see a significant impact on your business’s bottom line. So why wait? Simplify your strategy today and start seeing the results you’ve been dreaming of.

Marketing Automation: What It Is & How to Use It

)

Image Source: storyblok.com

Image Source: creatio.com

Image Source: svdcdn.com

Image Source: rocketcrm.co.uk

Image Source: googleusercontent.com

Image Source: ctfassets.net

Image Source: fuzen.io

Image Source: nix-united.com